Evolution of Laminates Market in India – Sarada Prasad Sahoo

The Indian laminates market began to grow in the late 20th century. It was primarily driven by increasing urbanization and the growth of the construction industry and the real estate sector. The Post-1991 economic reforms in India further gave it an impetus, leading to increased foreign investment and technology transfer, which boosted the laminates industry in the country. Another major reason for its growth since then has been the rising income levels of Indian households and changing customer preferences, which is veered towards aesthetically appealing and durable interior solutions.

Evolution in the 21st Century

By 2000s, the laminates market was flourishing, but it was limited to a small population. During this time, laminates on offer were basic in nature, with limited designs and colors – used primarily for functional purposes, such as in kitchens and furniture. However, in the last 20-odd years, a lot has changed in the laminates market, especially, in terms of customer choices.

Thin vs Thick

In the early 2000s, thin sheets of 0.5 mm to 0.8 mm were mostly preferred over thicker sheets, with colorful glossy ones being much in demand. The reason for this was the higher pricing of thicker sheets as well as those with texture. In addition to the price consciousness, the lack of awareness about laminates meant that most people were losing out on the benefits of thicker sheets – less prone to warping or bending under stress, better resistant to impact and physical damage, chipping or cracking and most importantly, longevity.

However, in the past decade, with the increased demand for architects and interior designers, who are well versed with the usage of laminates, its characteristics and its long-term benefits, the scenario has changed. With them sharing their knowledge and expertise about laminates with their clients, there has been surge in demand and preference for laminates with thickness of 0.8 mm, 1 mm and above.

Paint vs Inner Laminates

This was also the time when inner laminates or liners (laminates applied on the inner side of furniture) were not something people opted for. Getting inner portions of the furniture painted was the norm.

However, this practice changed as slowly people realized that the price of applying laminates in the furniture inner parts and getting them painted was costing them almost the same. Over that they were getting more pleasing appearance that painted surface (prone to dust) could not give. Today, it is quite rare to find furniture at homes without inner laminates; it has become the new and essential norm.

Design Options: Limited vs Plenty

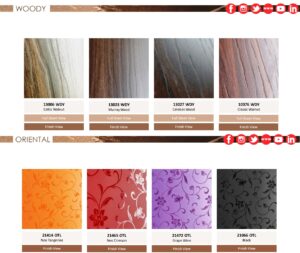

Another major change that has happened in the last 15-20 years is that previously the catalogues of laminate companies used to have 100 to 200 designs (with texture-based designs being only 10-20 per cent), but today, the catalogues feature more than 900-1000 design options. This is because of the growing demand and varied preferences of the customers.

Present Day Scenario

Today, with the introduction of advance technology – high-pressure lamination and digital printing – in laminate production, laminate companies are able to produce superior quality and a wide variety of laminates to meet the diverse taste of the customers. Another crucial step that these companies have undertaken is their shift towards environmentally friendly products, with adoption of green practices and use of sustainable raw materials.

At present, customers can find laminates in an eclectic range of colors, textures, types and finishes, based on the type of material that is being laminated. Some of the most sought-after laminates today include matt finish, super-matte finish, gloss-finish, textured, metallic, acrylic-finish, PVC and edge banding. These laminates have characteristics, such as abrasion-resistant, water-absorbent, anti-bacterial, anti-slip and anti-stain.

Future Trend

The future of the laminates market not just in India, but globally looks quite encouraging since people are inclining more towards fashionable products, with a lot of stress on customization and aesthetic values without being price sensitive. For any industry, these are great signs. In terms of designs and texture, a lot of innovation might be seen but when it comes to thickness of laminates sheet, there is less possibility of much change.

The market is expected to continue evolving, driven by ongoing urbanization, real estate development, and rising consumer aspirations. Continued integration of advanced technologies and materials is likely to enhance product offerings and market reach in the future.

About Author

Sarada Prasad Sahoo, Branch Manager, Odisha, Merino Industries Limited, has 20+ years of experience in the laminates industry. He has worked extensively in Eastern India and has a great understanding of the tastes and preferences of customers of this region.